Discover the Versatile Use Membrane Switch Over in Modern Electronics

In the world of contemporary electronics, the application of membrane layer buttons is extremely comprehensive, spanning from sleek consumer gizmos to crucial clinical devices. These thin, flexible interfaces not just streamline device operation with their tactile responsiveness however additionally substantially enhance durability by resisting environmental dangers like moisture and dust. As industries remain to develop, the assimilation of membrane layer switches in equipment style is pivotal, promising not just to fulfill however go beyond the extensive needs of both functionality and visual allure. Discover more concerning just how these parts are forming the future of innovation.

Discovering the Role of Membrane Layer Switches in Consumer Electronic Devices

Why are membrane layer switches over so prevalent in customer electronic devices? Membrane layer buttons are cost-effective to make, making them an eye-catching alternative for high-volume manufacturing normal in customer electronic devices.

Moreover, these buttons are understood for their sturdiness and low maintenance. From microwave ovens to remote controls, membrane buttons offer a useful, straightforward interface that supports the vibrant nature of customer electronic devices.

Membrane Layer Changes in Medical Gadgets: Enhancing Individual User Interfaces

Membrane layer switches also play a substantial duty in the world of clinical devices, where they boost interface with their distinct benefits. These switches are particularly valued for their integrity and simplicity of sanitation, important in medical care atmospheres where sanitation is paramount. The smooth, sealed surface area of membrane layer switches permits for easy sanitation, decreasing the danger of contamination and spread of microorganisms. Furthermore, their style versatility suits the aesthetic and ergonomic demands of clinical equipment, making tools a lot more user-friendly and accessible for health care experts.

Membrane buttons also contribute to the resilience of clinical devices. Their resistance to fluids and impurities ensures that vital devices continues to be functional in numerous medical setups, consisting of surgeries where direct exposure to liquids is common. important link This longevity, coupled with tactile responses and low-profile style, makes membrane switches over an important element in improving the efficiency and safety of medical gadget interfaces.

The Impact of Membrane Turns On Industrial Tools Design

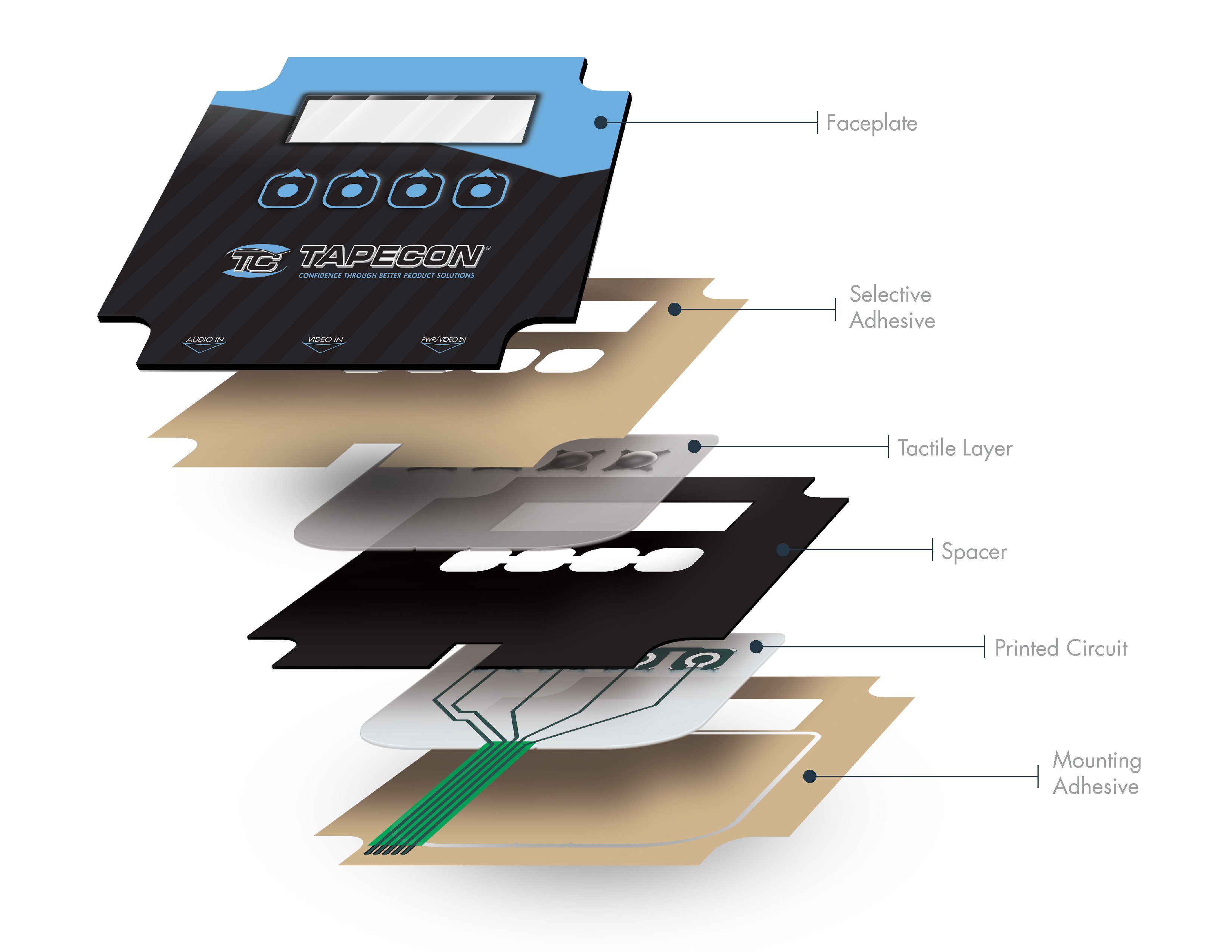

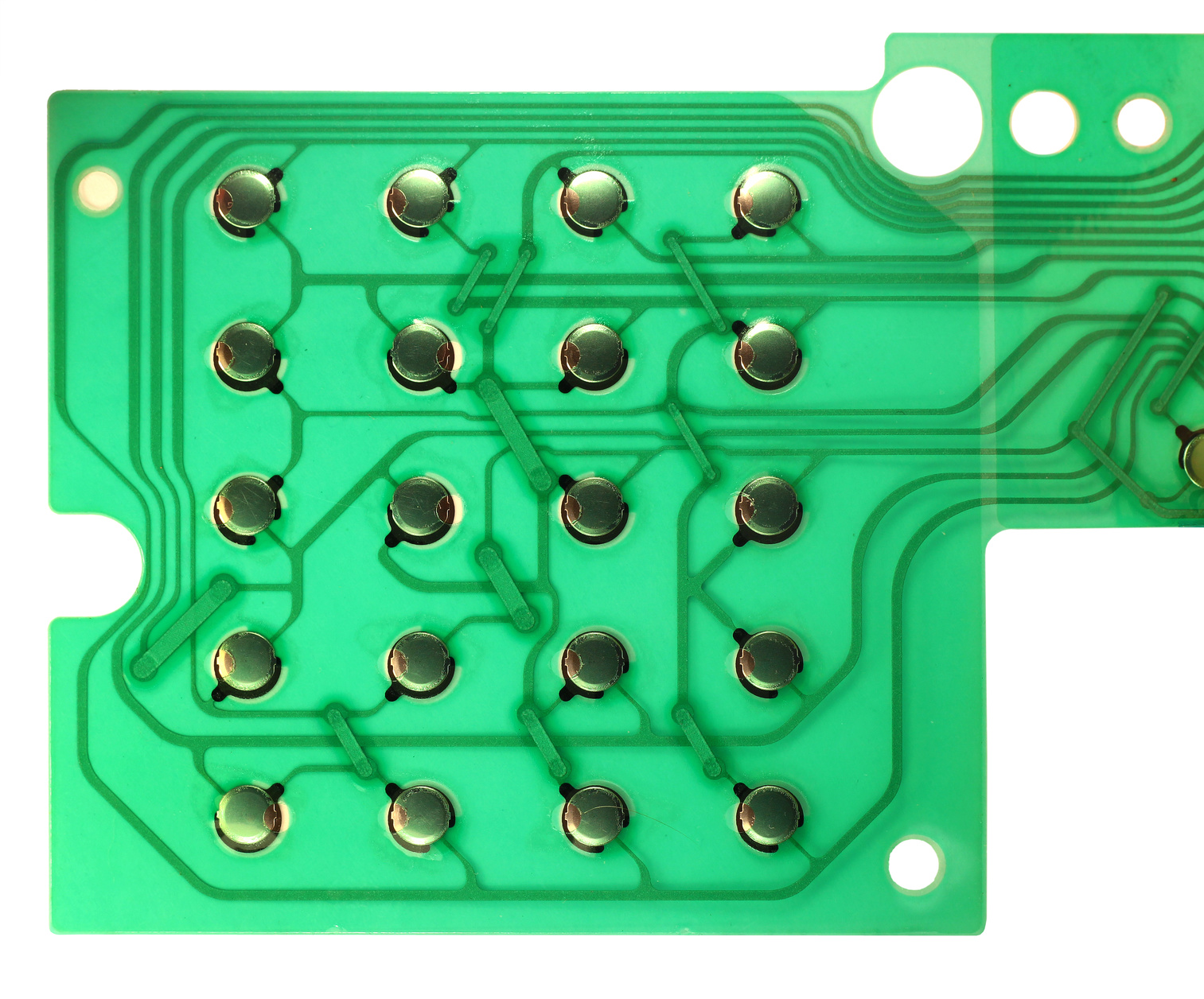

In the visit this site world of commercial tools design, the unification of membrane buttons has actually noted a substantial evolution. These buttons have actually changed how suppliers approach user interface performances, offering a blend of durability and convenience that is essential in rough settings. The slim profile of membrane changes permits even more portable machine styles, while their resistance to chemical, dirt, and water contaminants makes them ideal for industrial setups. This flexibility has actually facilitated the development of tools that is not just more durable yet likewise less complicated to preserve and tidy, thereby minimizing downtime and functional costs.

Furthermore, the customizability of membrane changes allows designers to integrate details responsive feedback and graphical overlays that boost the individual experience and increase effectiveness. This combination supports operators in achieving accuracy control over complicated machinery. The overall influence is a significant find more information improvement in the capability, dependability, and user-friendliness of industrial devices, lining up with the boosting needs for technical improvement and functional effectiveness in modern-day markets.

Verdict

Membrane switches have actually changed modern-day electronics, supplying smooth, durable, and customizable user interfaces across different industries. This technology not just satisfies the demanding conditions of various areas however also considerably enhances user experience, making membrane layer changes a cornerstone of modern electronic style.

In the realm of modern-day electronics, the application of membrane layer buttons is extremely comprehensive, extending from streamlined customer gadgets to essential clinical devices.Why are membrane switches over so widespread in customer electronics? Membrane layer buttons are cost-effective to make, making them an appealing choice for high-volume manufacturing normal in customer electronic devices. From microwave stoves to remote controls, membrane buttons give a functional, easy to use user interface that supports the dynamic nature of customer electronic devices.

Comments on “Ensure Better Usability with Membrane Switch for High-Precision Applications”